-

Products

View -

Select Your Vehicle

Change - Go

- No Favorites

ARB SAHARA BUMPER

Unlike most brush guards and bumpers, ARB Sahara bumpers incorporate a fully engineered mounting system which completely replaces the factory bumper. ARB’s Sahara bumper selection is the most stylish in the ARB bumper line. A lower bumper unit fitted with a Chrome Hoop for enhanced styling and greater grill protection. Loaded with features aimed at making remote area travel safe, no other bumper offers the same degree of vehicle integration, protection or functionality.

BULL BAR PRODUCTION STEPS

LASER CUTTING

Every bull bar starts its life as a flat sheet of steel. Individual components are cut to shape using ARB’s state of the art, computer aided laser cutters which can cut to a tolerance of just 0.2mm with no heat distortion, resulting in superior surface finishes and accuracy.

FOLDING

Individual components are then folded to make up the sections of the bull bar using a Computer Numerically Controlled (CNC) machine which ensures maximum accuracy and consistency. Most bull bars utilise ARB’s five fold design, with each fold providing additional strength.

TUBE WORK

ARB bull bars are made with strong, 2.6mm wall thickness tubing. The tube is cut to the desired length and bent with a CNC Eagle internal mandrel bender ensuring consistency, accuracy and an even wall thickness across all sections.

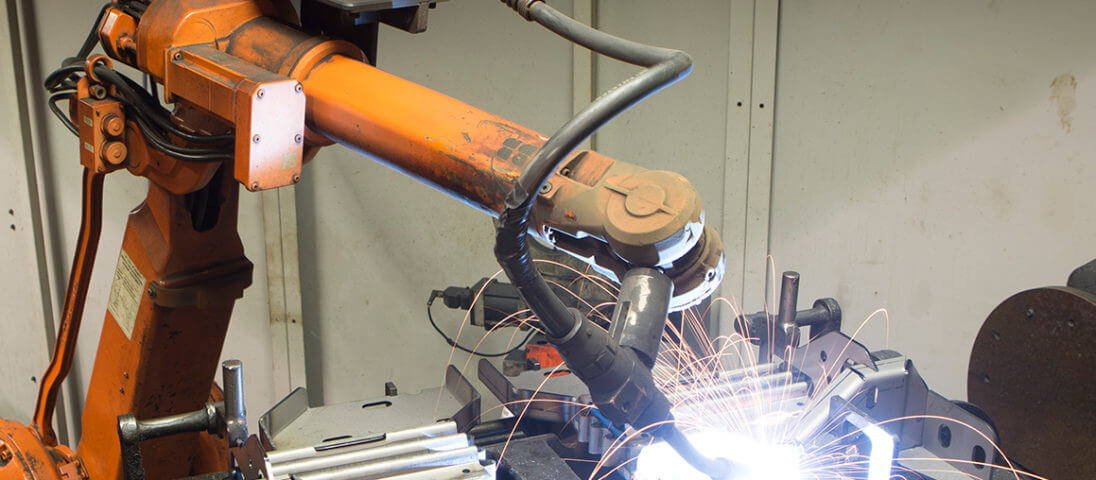

ROBOT WELDING

Once folded, each section is welded utilising a robot welder. Robot welders are used for straightforward, repetitive welding jobs that require deep penetration, speed and accuracy.

ASSEMBLY

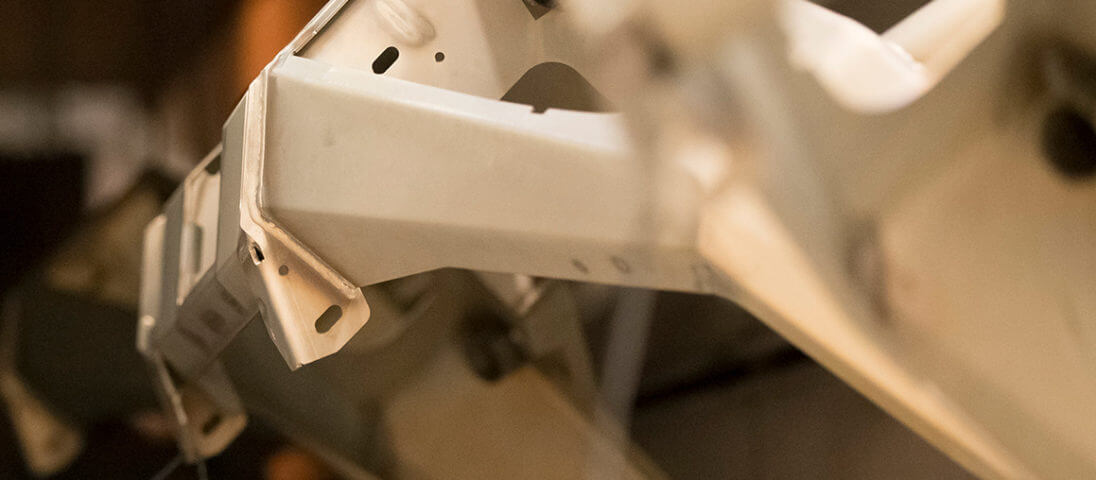

When individual components are complete, the bull bar is assembled. All sections including pan, wing, uprights, outer frame and chassis brackets are placed in a jig and tack welded. This is followed by finish welding and grinding for strength and aesthetics. Jigs are assessed regularly to ensure accuracy.

POST ASSEMBLY

To complete the manufacturing process all ARB bars are shot blasted, before entering a 5 stage chemical wash to prepare the surface for maximum powder adhesion. They’re then powder coated and oven baked to ensure a rich and durable finish. As well as being an attractive and durable finish, power coating provides an excellent base for painting if colour coding is required.

Uncover the gear as well as some tips and tricks you will need for your next adventure off grid! Read here!

View online or order a printed copy

Enter your email address to receive updates about our products and events as well as newsletters.